Precision Turret Punching Services in Melbourne

- Home

- Precision Turret Punching Services in Melbourne

If you are looking for Turret Punching Services in Melbourne, your project likely needs clean results, consistent dimensions, and parts that assemble without headaches. Turret punching is designed for exactly that work. It is widely used when sheet metal components require repeated holes, precise patterns, or formed features that must remain accurate from the first to the last part.

At Swift Metal Fabrication, turret punching is treated as a practical manufacturing solution. Backed by modern CNC equipment and 55 years of combined experience, our Melbourne-based team supports projects of all sizes, from one-off parts to ongoing production runs. If you already have drawings ready, you can send them for a fast and clear quote.

What Is Turret Punching and When Should You Use It?

Turret punching is a sheet metal process that cuts and forms components using a computer-controlled punch press rather than heat. The process is well-suited to parts that need repeatable features and consistent accuracy without the risks associated with thermal cutting methods.

How turret punching works

A turret punch press uses a rotating tool system fitted with multiple punches and dies. Each tool is selected automatically based on the programmed file, allowing holes, cut-outs, and formed features to be produced in one continuous production cycle. The sheet is positioned under precise CNC control, so every strike lands exactly where it should.

This level of automation allows tight tolerances, typically around 0.02 mm, which is critical when parts need to align with folds, fasteners, or adjoining components. Because the process is repeatable, results remain consistent across batches, whether you need a small quantity or a full production run.

Jobs turret punching is best suited for

CNC turret punching is ideal for:

- Repetitive holes and slots

- Vent and airflow patterns

- Knock-outs and cut-outs

- Parts that require forming without secondary operations

When repeatability, speed, and formed features matter, turret punching often provides a cleaner and more predictable outcome.

Our Turret Punching Capabilities

Swift Metal Fabrication operates modern CNC turret punch equipment built for accuracy, reliability, and efficiency throughout. Multiple tool stations enable different features to be produced in a single stage of production, keeping handling time low and results predictable.

Forming and punching features

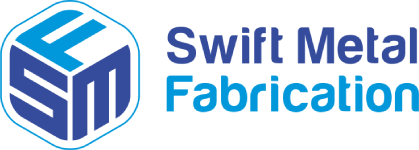

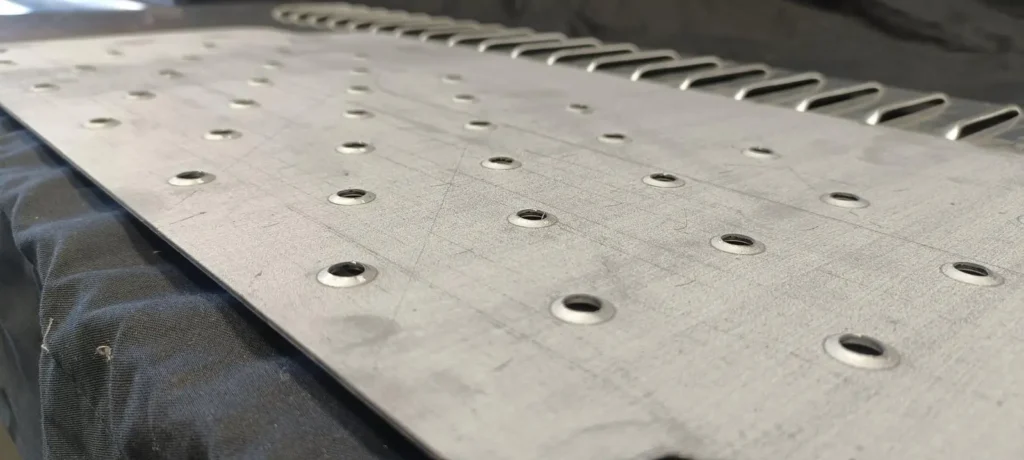

Our turret punching capabilities include round, square, and slotted holes, precision cut-outs, ventilation louvers, countersinks, electrical knock-outs, lance and form features, and embossed details. Because these features are programmed and controlled, parts remain consistent across both short runs and larger orders.

Materials and Thickness Ranges We Process:

Clear material limits help set realistic expectations and build trust. At Swift Metal Fabrication, CNC turret punching is used across a range of common sheet metals:

- Mild steel: up to 3 mm

- Aluminium: up to 4 mm

- Stainless steel: up to 2 mm

- Galvanised and zinc-coated steel: up to 3 mm

These ranges allow flexibility across many industrial and commercial applications while maintaining clean, consistent results. We combine state-of-the-art Amada machinery with decades of hands-on expertise to deliver high-quality outcomes without compromise.

Maximum Sheet Size and Production Capacity

Sheet size directly affects what can be produced efficiently. Our turret punching capacity supports sheets up to 750 mm by 3000 mm, with up to two repositions for longer components. This flexibility allows extended panels and larger parts to be produced without sacrificing accuracy.

This capacity supports prototypes, short production runs, and higher-volume orders. Rather than simply listing numbers, the real value lies in efficient nesting, controlled handling, and consistent output across every batch.

Why Choose Swift Metal Fabrication

for Turret Punching Services in Melbourne?

Choosing a turret punching provider is about more than machinery. It comes down to experience and judgment developed over time.

Swift Metal Fabrication brings 55 years of combined hands-on experience, modern CNC turret punch equipment, honest advice on process selection, and local Melbourne-based support. With end-to-end fabrication capability available when required, projects stay coordinated rather than split across multiple suppliers. This practical approach builds trust and delivers outcomes that match the drawings, not just the quote.

Turret Punching vs Laser Cutting

Laser cutting and turret punching are both common in modern fabrication, but they are not interchangeable. Each method suits different materials and design requirements.

Where turret punching has the advantage

Turret punching is particularly effective when parts require features such as louvers, countersinks, lance and form details, or embossing. These can be produced during the punching cycle rather than added later. The process is also faster for repetitive patterns because it does not pause between features.

Another key advantage is the absence of heat. Because turret punching relies on mechanical force, there are no heat-affected zones. Painted or coated materials, including Colorbond, retain their surface finish rather than becoming scorched or discoloured during processing.

Materials problematic for laser cutting

Some materials are difficult or risky to process with a laser. These include:

- Brass

- Copper

- Pre-finished or reflective materials

Highly reflective metals can damage laser cutting equipment, while pre-finished surfaces can lose their appearance. Turret punching avoids these issues by using mechanical force instead of a laser beam. This is a gap, yet it is often the deciding factor for manufacturers.

Design and File Preparation Support

Good results start with good information. Clear files reduce setup time and help prevent issues during fabrication.

Preferred file formats

For turret punching work, DXF or DWG files are preferred for flat patterns, supported by PDF drawings for reference where needed. Marked-up drawings are also accepted if clarification is required.

What we check before punching

Before production begins, we review hole sizes relative to material thickness, edge distances to avoid distortion, tooling suitability for formed features, and pattern alignment for repeatability. This upfront review often prevents problems later during folding, welding, or installation, saving time and cost across the project.

Quality Control That Protects Fit, Function, and Assembly

Accuracy only matters if it stays consistent. CNC Turret punching provides mechanical precision, but quality control keeps results reliable from the first part to the last.

Our approach focuses on first-off part checks, dimensional consistency across batches, and clean punching that supports downstream fabrication. Parts are produced so they align correctly during folding and welding, reducing adjustments during assembly and installation.

From One-Off Parts to Production Runs

One of the strengths of turret punching is flexibility. Setup times are short, and programs can be reused for repeat orders. This makes the process suitable for one-off parts, prototypes, and ongoing production work without sacrificing turnaround time or quality.

For Melbourne businesses managing tight schedules or repeat projects, this consistency makes turret punching a dependable manufacturing option.

Let’s Get Your Project Work With CNC Turret Punching Services

Turret punching is not about choosing the most complex technology available. It is about selecting the process that delivers accuracy, consistency, and reliable results for the job at hand. When those outcomes matter, Turret Punching Services in Melbourne from Swift Metal Fabrication offer a practical solution backed by real fabrication experience.

FAQs About Turret Punching Specialists

It is used to cut and form sheet metal components with repeated holes, patterns, and formed features using a punch press.

It is often preferred for repetitive features, formed details, and materials that are reflective or pre-finished.

Turret punching delivers strong dimensional consistency, making it well-suited for parts that must align during folding, fastening, or assembly. Accuracy is typically within tight tolerances when files are prepared correctly, and tooling is matched to the material. This level of repeatability is especially valuable for panels, brackets, and components produced in batches where every part must fit the same way.

Common materials include mild steel, aluminium, stainless steel, and galvanised or zinc-coated steel within defined thickness ranges.

Pricing is influenced by several practical factors rather than just part size. These include material type and thickness, number of features per part, overall quantity, and file readiness. Parts with repeated patterns or standard features are generally more efficient to produce, while poorly prepared drawings or late design changes can add time. Clear files and accurate quantities help keep costs predictable.